Technoid Tower M-CDC Workshop

Workshop on digital design and fabrication in Architecture, by Hans Sachs (responsive design studio) and Sebastian Bächer (Bächer & Bergmann GmbH). This workshop is part of the international Master Program Computational Design & Construction (MCDC) at the University of Applied Sciences Ostwestfalen- Lippe in Detmold, Germany.

Digital manufacturing processes are rather related to the principles of crafts than industrial production as they emphasize the wide range of qualities of the materials used and provide higher flexibility and extensive opportunities during the development and production process. With the use of new, integrative ‚digital design and fabrication tools‘ the boundaries between design development and production become increasingly blurred.

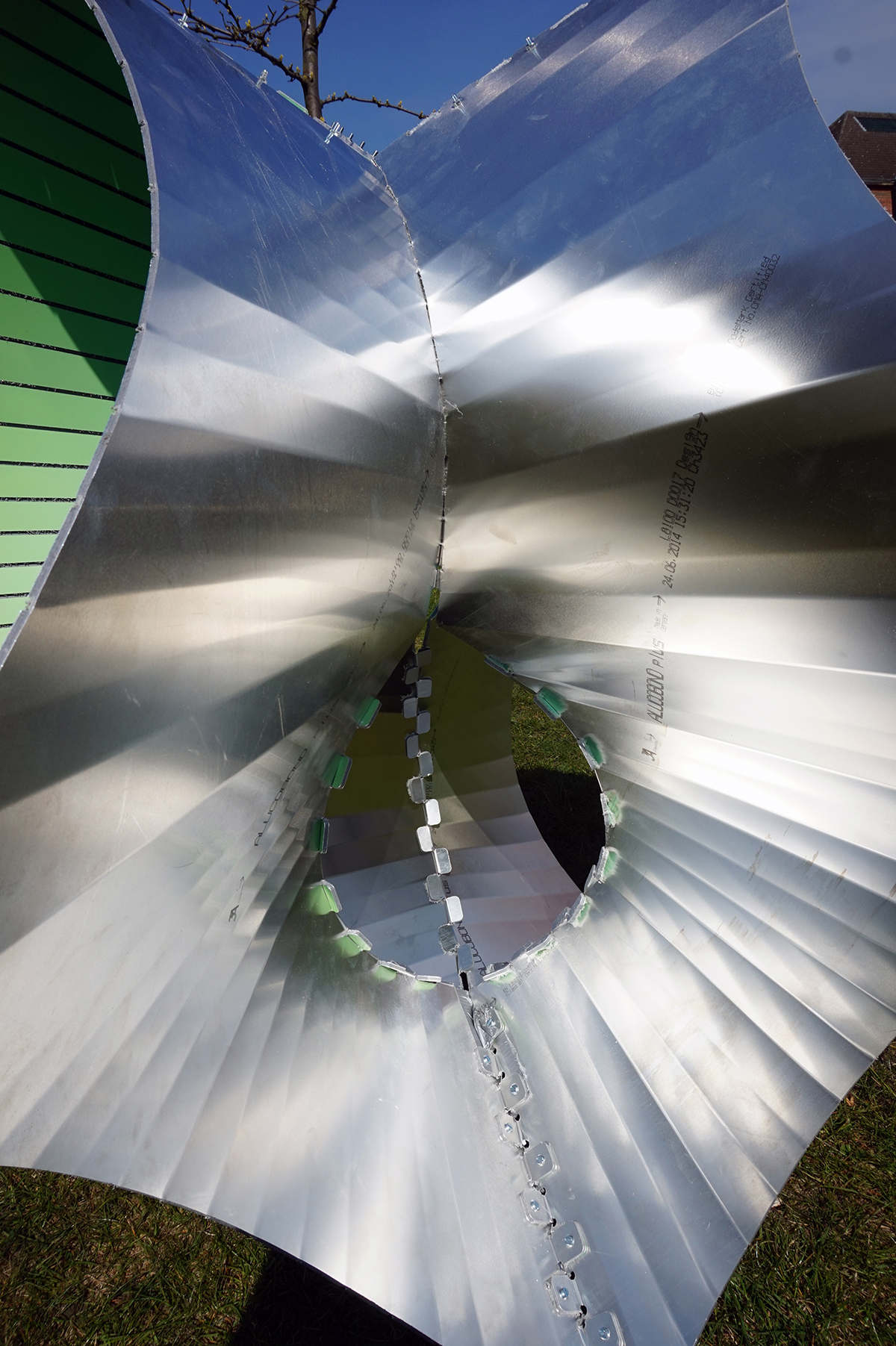

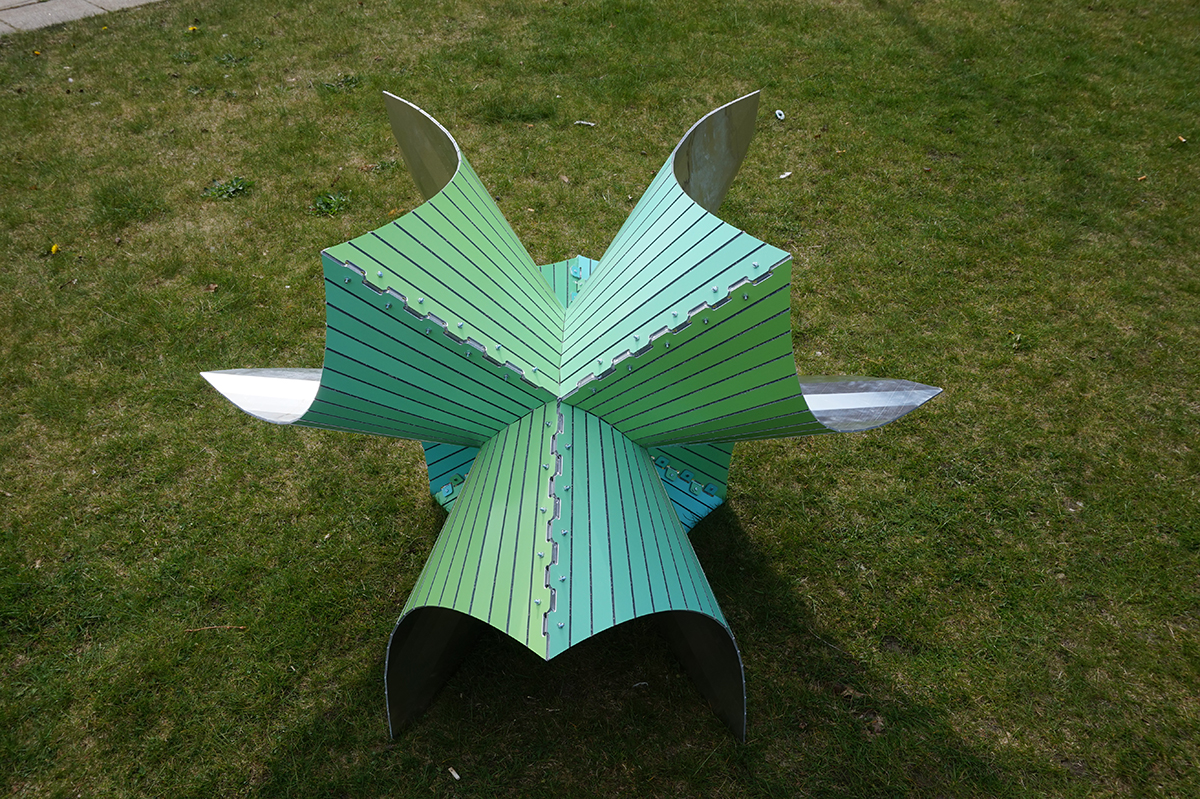

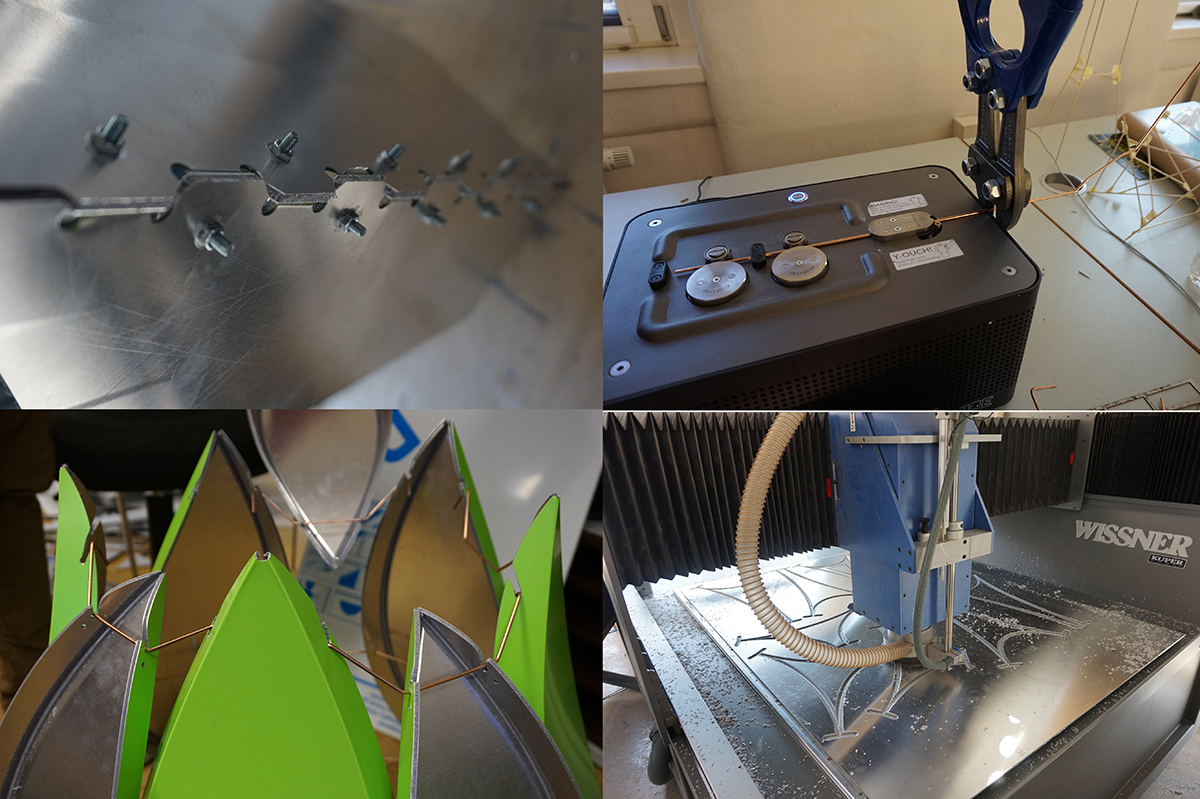

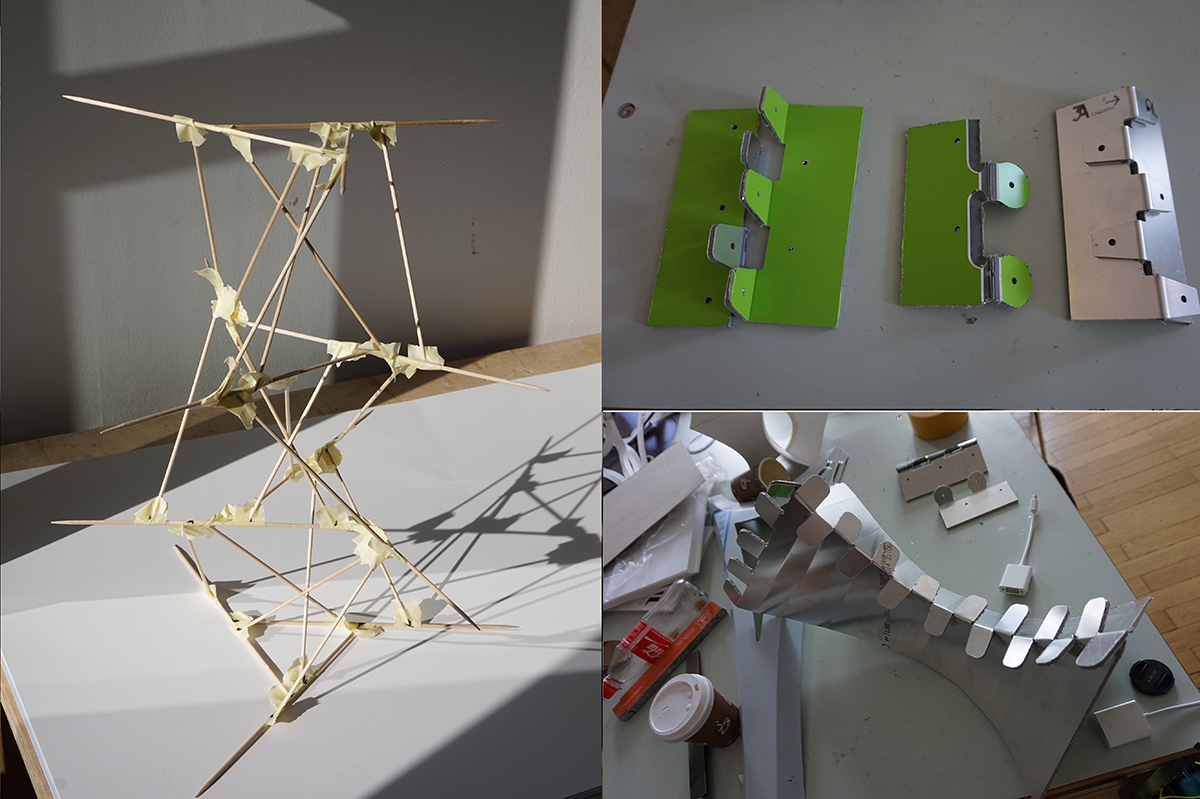

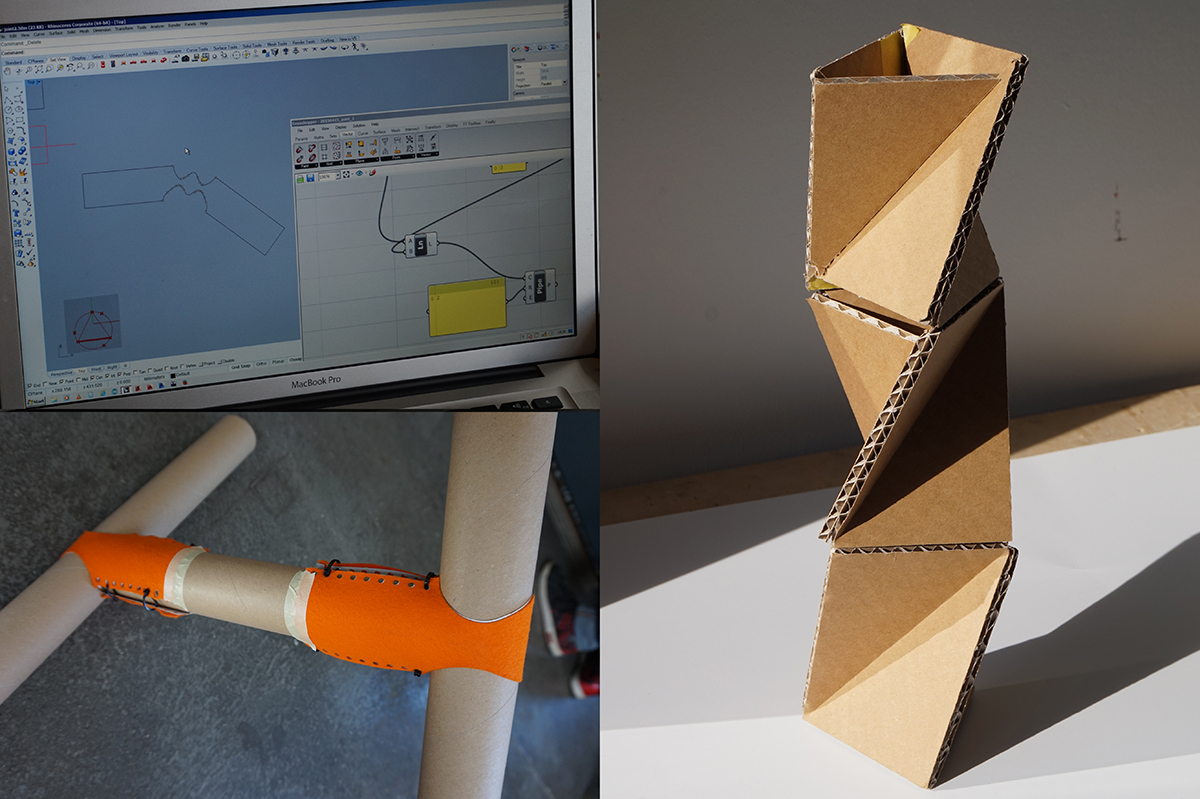

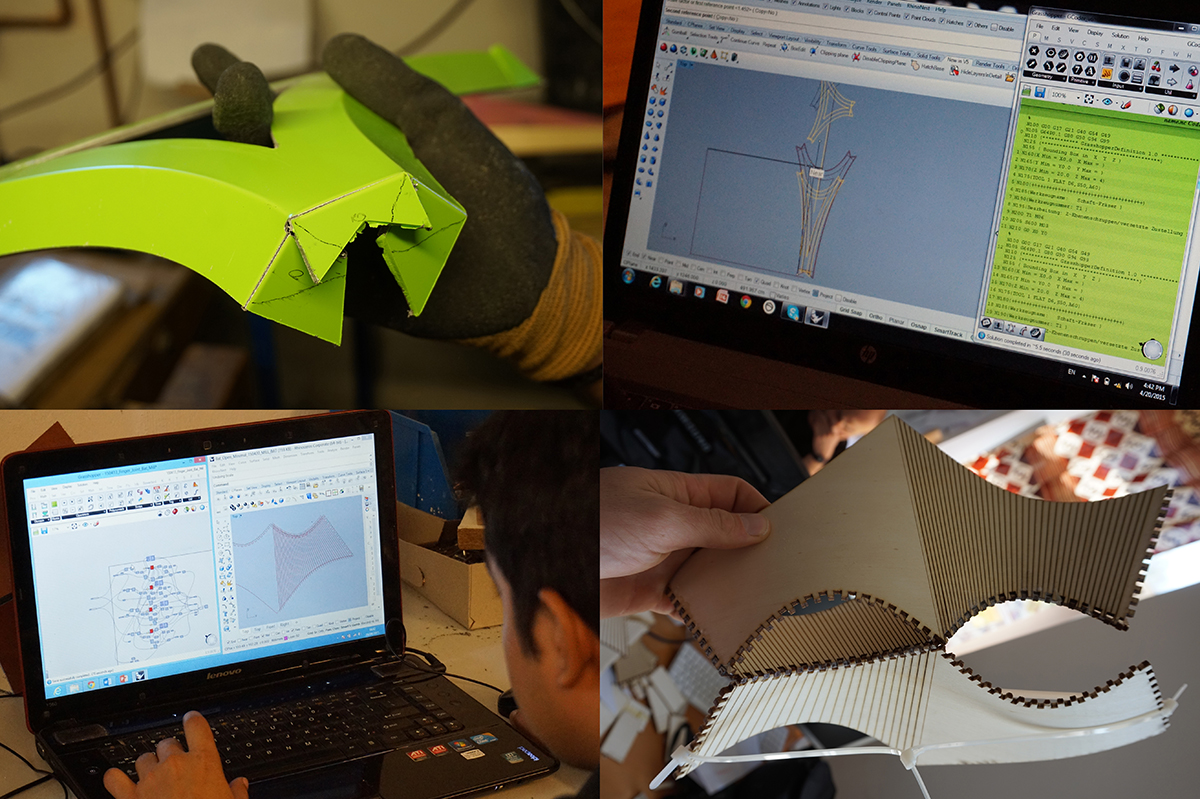

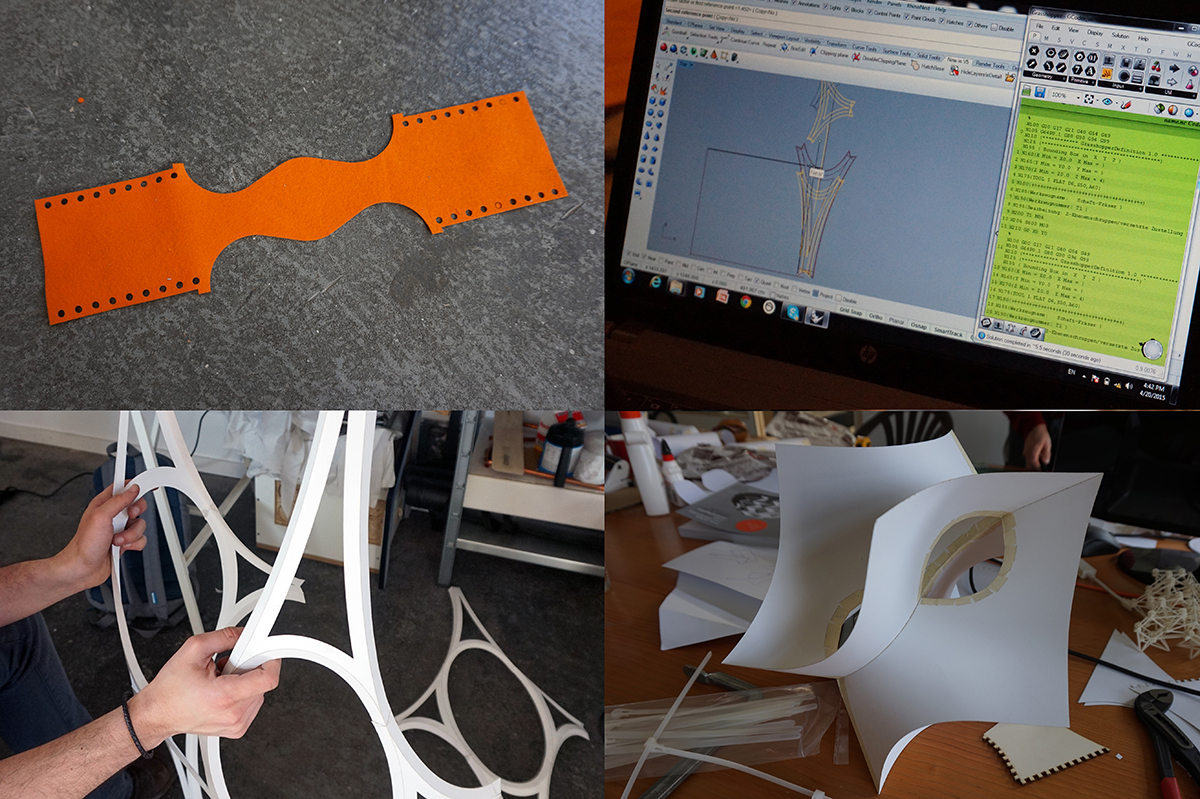

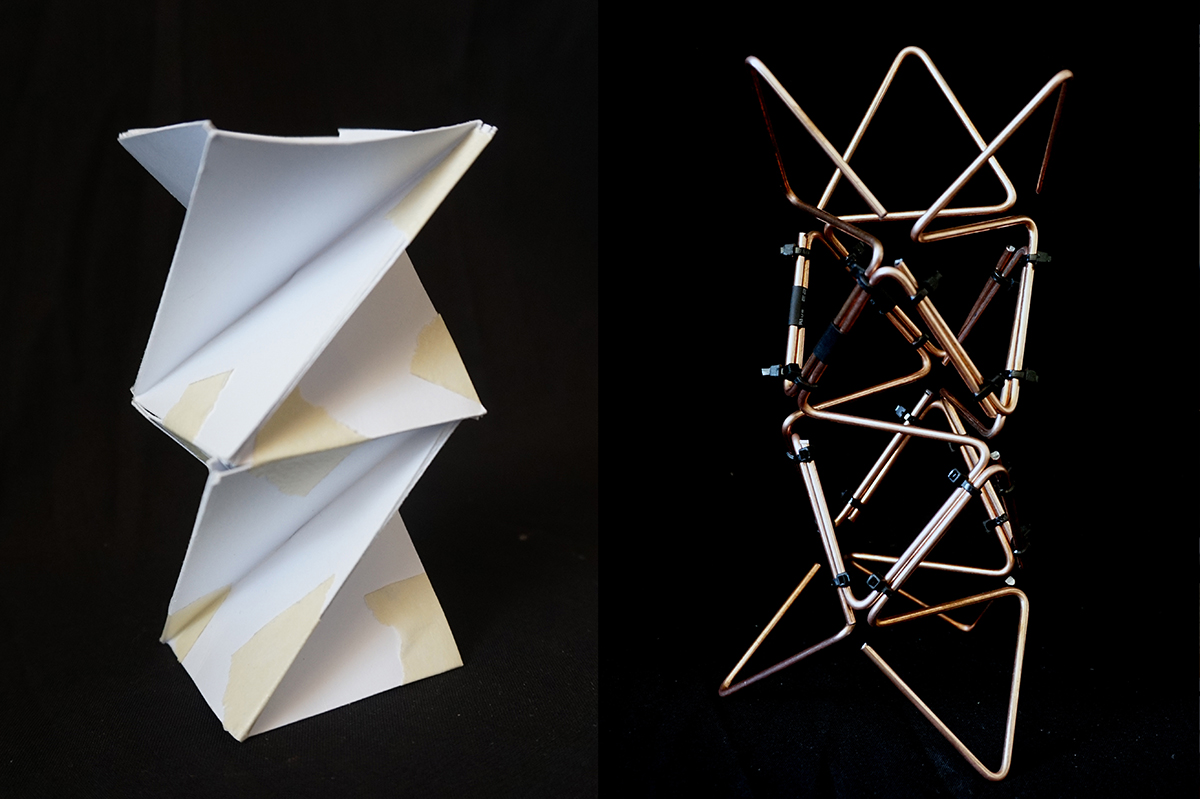

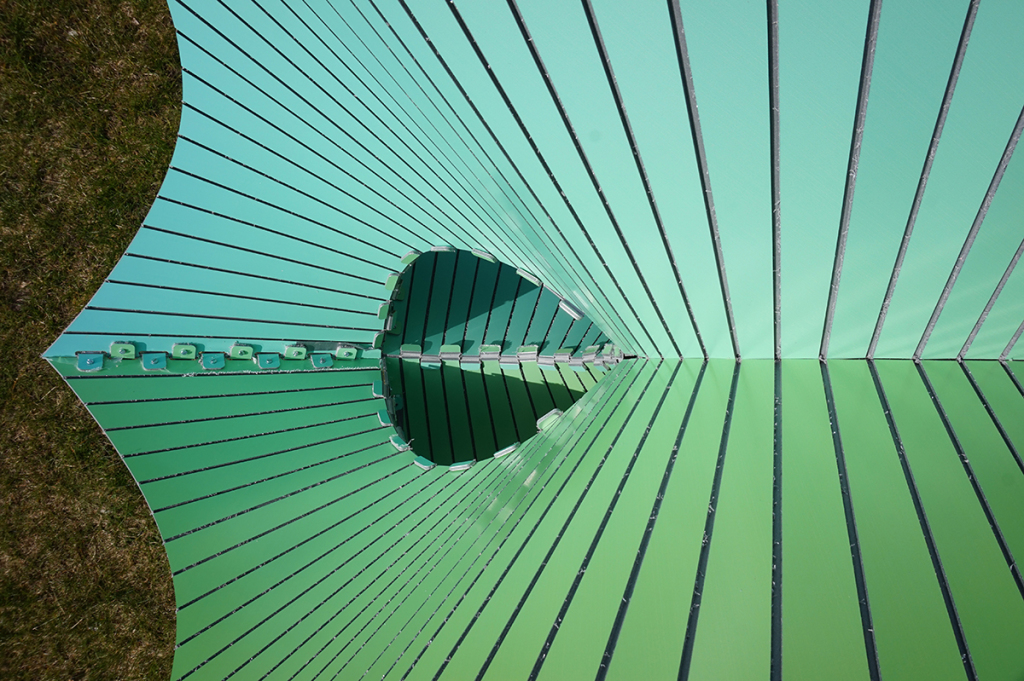

In this workshop, students developed their concepts and prototypes of folded structures and towers with semifinished, foldable aluminum composite materials (i.e. AluCoBond®) and cardboard pipes. With a, especially for this workshop developed, Grasshopper 3D (Visual programming for Rhino 3D) definition, the students could immediately realize first ideas as ‚real’ prototypes. With this work flow the students could implement conclusions about material behaviour and properties during manufacturing processes into their digital models in a much faster and direct way. The software directly generates G-Codes (without CAM Software) for various CNC machines based on the 3D model data, which leads to a highly accelerated and tightly focussed prototyping and development process.

The realized prototype structures result from an highly integrative process of hand- and digital-work. Each student developed his own structure by developing a digital tool for form finding (modelling) and fabrication. Every project realization took only 2 weeks from the first sketch or model to the final structure.

The workshop has been kindly supported by 3A Composites AG.

students:

Arjun Sharma, Alexander Fillies, Suraj Sunil Kumar Shetty, Ahmed Moharam, Boris Bähre