Digital Crafting KISD

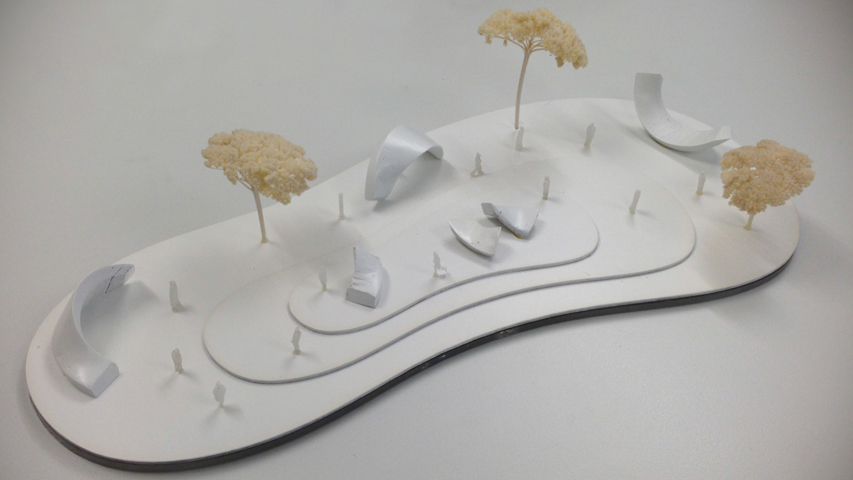

In a 10 day workshop the students from KISD – Köln International School of Design have been encouraged to develop a design project based on a buttom-up design process – ‘material and process to form’ (instead of form first, material later) by experimenting with material properties and computer based processing techniques, such as 3D printing and CNC milling…

With the integration of digital tools in design and production processes ,the boundaries between design, development and production become increasingly blurred.

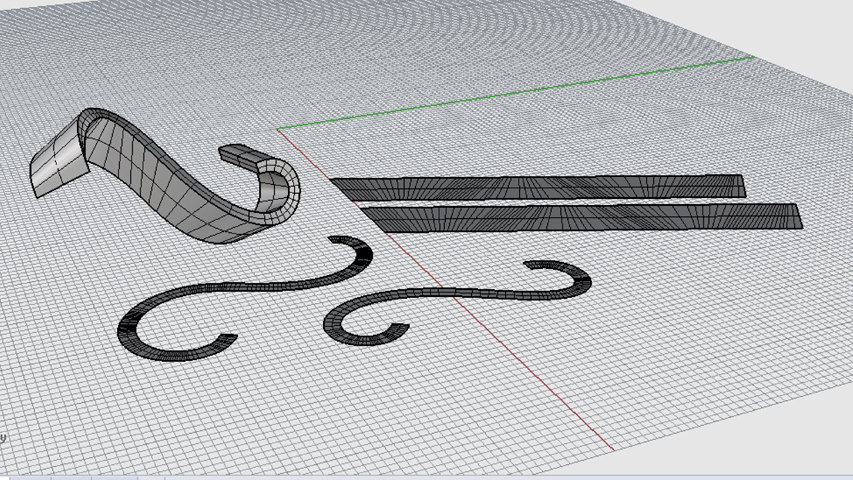

Material properties ,certain environmental variables and constraints – i.e. user input data – in combination with digital, rule-based production processes significantly characterize the process of form-finding. After the era of industrial production, the possibilities of computer-aided design and manufacturing revive some fundamental principles of traditional craft and inevitably lead to new design aesthetics.

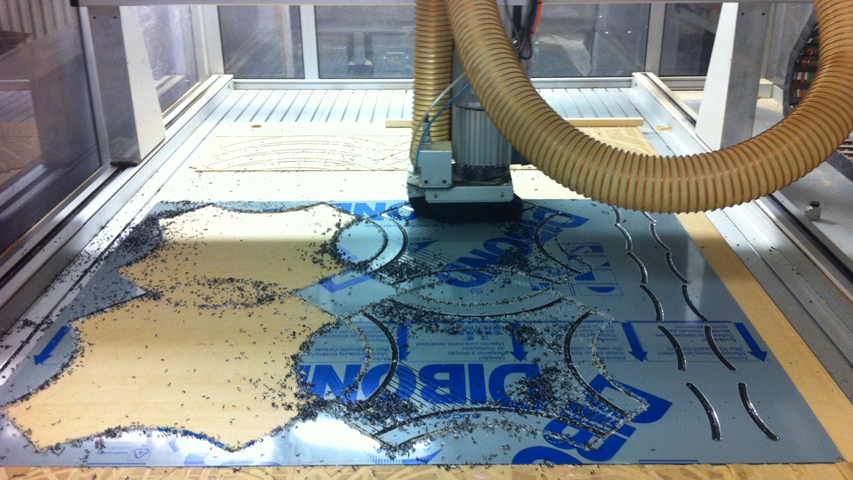

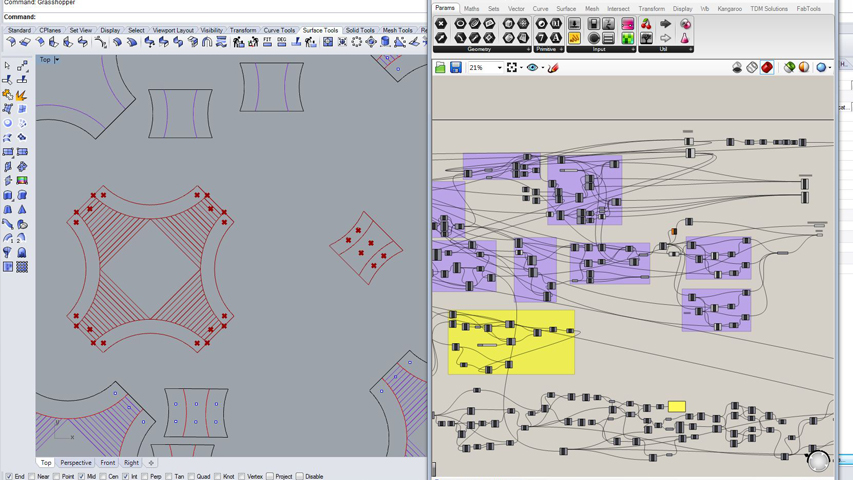

The aim of the workshop is the experiment with selected materials in conjunction with the computer-based processing techniques. The link between the design and production processes represents one of the main aspects of the course. Students use the 3D modeling software Rhinoceros 3D and the associated plugin Grasshopper 3D to “program” a certain material (semi finished material). They develop their own ” digital shaping tool” with which they directly generate CNC machining code (G-code) for a CNC device in the KISD factory.

Special thanks to

Manuel Kniepe MK-Stern Fotografie

3A Composites

Prof. Andreas Muxel, Interface Design, KISD

supervisor

Sebastian Bächer, Hans Sachs

selected projects of students

Carolina Menezes, Philipp Funke, Niklas Ißelburg, Toni Jörg Max Fred Groß

location

KISD, Cologne, Germany

date

28.3. – 11.4.2014